Replenishment and Kanban Bin#

Overview#

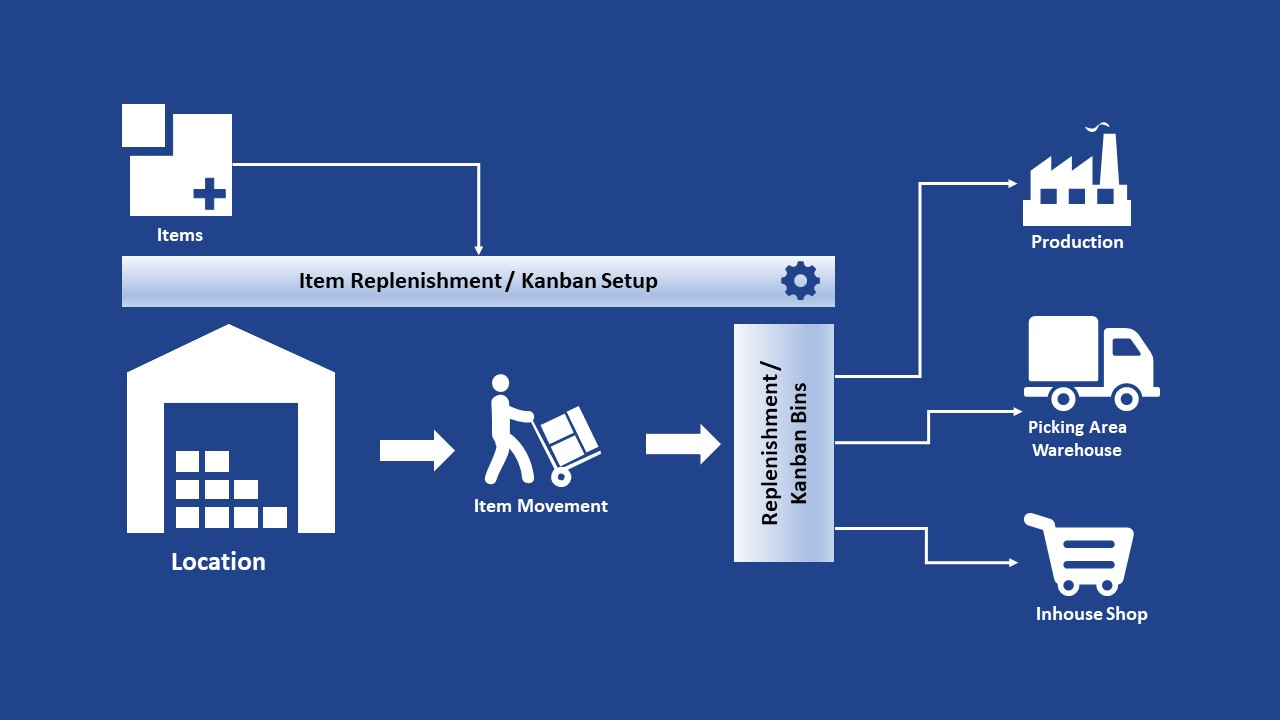

The app "Replenishment and Kanban Bin" supports you in the consumption-based bins transfer of material. Defined location areas can thus be replenished automatically - even without a "controlled warehouse".

In doing so, the app offers you the following advantages:

- Optimization of warehouse processes

- Efficient organization of your warehouse

- Fast and flexible setup of the location areas

- Demand-driven determination of stock transfer quantities

- Time saving in the snacking area

The standard Microsoft Dynamics 365 Business Central1 process supports the user in stock transfers from bin to bin based on stockkeeping units and the request or planning lines.

The Replenishment and Kanban Bin App is designed to assist the user with a consumption-based bin transfer of material within a non-controlled location during putaway and picking.

Note

In order to obtain a meaningful result for the bin relocation, the execution must take place in the "off-peak hours" in the warehouse / logistics area.

Location bin transfers during operating hours, e.g. parallel picking and goods receipt / putaway, are not advisable as picking / putaway could have an unfavorable effect on the contents of the storage bin.

Introduction Replenishment and Kanban Bin#

Replenishment & Kanban Bin | KUMAVISION App from KUMAVISION on Vimeo.

Link to Microsoft App Source "KUMAVISION Replenishment and Kanban Bin"

Setup#

User authorization#

To assign the user the necessary authorizations for the replenishment and Kanban storage bin functionality, first call up the "Users" via the user search.

On the desired user card, you then have the option of assigning the intended authorization set "KVSKANRead" / "KVSKANSetup" to the user on the "User authorization sets" info tab.

Location#

The following points should be considered when setting up the storage location:

- You should configure locations directly with bins.

- These storage locations must not be configured as "Direct putaway and picking".

- The warehouse has two areas: Preferred picking area and replenishment area.

- Within these areas, the warehouse can be organized arbitrarily or with fixed storage locations.

This application is not suitable for a completely chaotic warehouse or a completely "directed storage and retrieval warehouse".

On the corresponding location map, the following setups must be made for the replenishment and kanban location functionality on the "Warehouse" info tab:

| Field | Description |

|---|---|

| Default KANBAN Item Reclass. Journal Template Name | In this field, enter from the item book. sheet templates List the stock transfer ledger sheet template for Kanban functionality. |

| Default KANBAN Item Reclass. Journal Batch Name | Enter in this field from the assigned item book.sheet templates the item book.sheet batch If this has not yet been created for the Kanban functionality, you can define it from the list via "New". |

Bins#

In the bins, the "Replenishment and Kanban Area" (Supply Area) is defined via the "Transfer Type" field.

To do this, call up the bins via the menu ribbon and set up the corresponding bin via the "Transfer Type" field.

| Option | Description |

|---|---|

| Replenishment and Kanban Area | Indicates the bins to which the stock is transferred, i.e. which are filled. |

| Supply Area | Indicates the storage bins from which stock is transferred. |

| Empty | For all bins that are neither "kanban area" nor "supply area", f.e. special bins like goods receipt bin code, goods issue bin code. For these bins it is also explicitly checked if the stock transfer type is "empty". |

Note

Please note that you define at least one bin as "Supply Area" and one bin as "Replenishment and Kanban Area".

Replenishment and Kanban setup list#

In a chaotic warehouse, an item can be located in any bin. There can also be several items in one bin. Therefore, the rules for the "Replenishment and Kanban bin" functionality are not located directly in the bin, but in a separate table.

The following should be noted here:

- Items maintenance is always performed manually

- Items that are not to be transferred do not receive inventory data

- Data maintenance is mandatory here

The calculation is based on the content of the bin in combination with the "Transfer type" of the bin. Only bins with the "Transfer type" = Kanban area are taken into account.

You can configure replenishment for the items in the "Replenishment and Kanban Setup List". To do this, call up the "Replenishment and Kanban Setup List" via the user search. Via "New" you can define a new data record with the help of the table below.

| Field | Description |

|---|---|

| Location Code | Specifies the storage location code. |

| Item no. | Specifies the item number. |

| Variant Code | Indicates the variant of the item (if any). |

| Item Description | Indicates the item description of the item. |

| Minimum Quantity (Base) | Specifies the minimum quantity (base). If the minimum quantity per item is fallen short of (sum of all storage bins with "transfer type" = picking area), a refill / stock transfer is triggered. |

| Replenishment Quantity (Base) | Specifies the replenishment quantity (base). Suggested replenishment quantity calculated for all storage bins with "Stock transfer type" = supply area. The replenishment logic corresponds to the "fixed order quantity" replenishment procedure for the external procurement of an item. |

| Auto. Change Qty per Batch | Check the box if you want to allow automatic change of the quantity per batch. For the calculation of the two fields Minimum Quantity (Base) and Replenishment Quantity (Base), a function is available for the regular revision of these data. |

Note

Please note that at least one item is set up with a "Minimum Quantity (Base") and one item is set up with the "Replenishment Quantity (Base)".

Recalculation of quantities in replenishment and Kanban storage bins#

A function for the initial creation and regular revision of the above data structure or the "Minimum Quantity (Base)" and "Replenishment Quantity (Base)" fields is available for maintaining the kanban stock data.

The function is called up via the user search using the search term "Calc. SKU Replenishment Kanban Setup Quantities".

The "Minimum Quantity (Base)" field is calculated on the basis of monthly values. All expenses for the location, bins of the "Transfer Type" = Kanban area for the respective item (and variant) in the corresponding period are taken into account.

The replenishment quantity (base) is calculated from the field Minimum quantity (base) * Factor for replenishment quantity.

Process#

Essentially, there are two procedures for the bin transfer proposal:

- Manual call of the function from the Item Reclassification Journals

- Periodic call of the function ("Calculate bin replenishment") in the task queue items.

In the following, these two function options will be explained to you in more detail.

Manual filling via the Item Reclassification Journals#

Call up the "Item Reclassification Journals" via the user search and execute the "Cal. Bin Replenishment" function via the menu ribbon.

After executing the function, the journal for the item transfer is filled accordingly. With the function "Cal. Bin Replenishment", only locations are taken into account where the items has already been posted once and the minimum quantity is not reached. The journal can be modified and deleted manually. The function can be executed any number of times.

Periodic automatic filling of the Item Reclassification Journals#

The "Job Queue Entries" can be used to automatically refill during the night, for example.

The fields on the "General" info tab can be filled as follows:

| Field | Description |

|---|---|

| Status | Wait and see |

| User ID | "ADMIN" |

| Object Type to Run | Report |

| Object ID to Run | 70260117 |

You can use the "Report request page options" filter to use the filters of the report. Moreover, they will be saved and used automatically when the report is run automatically.

| Field | Description |

|---|---|

| Delete existing lines | Deletes the already existing lines of the report |

| Storage bin code | Filters according to the bin code |

| Location code | Filters by the storage location code |

| Item no. | Filters according to the item no. |

| Variants code | Filters by variant code |

Print#

The print view of the book sheet can be used as a picking document to perform the stock transfer in the warehouse.

Book#

The "Post" or "Post and Print" calls post the book sheet after the physical stock transfer.

Application examples#

Application in trade#

Example 1#

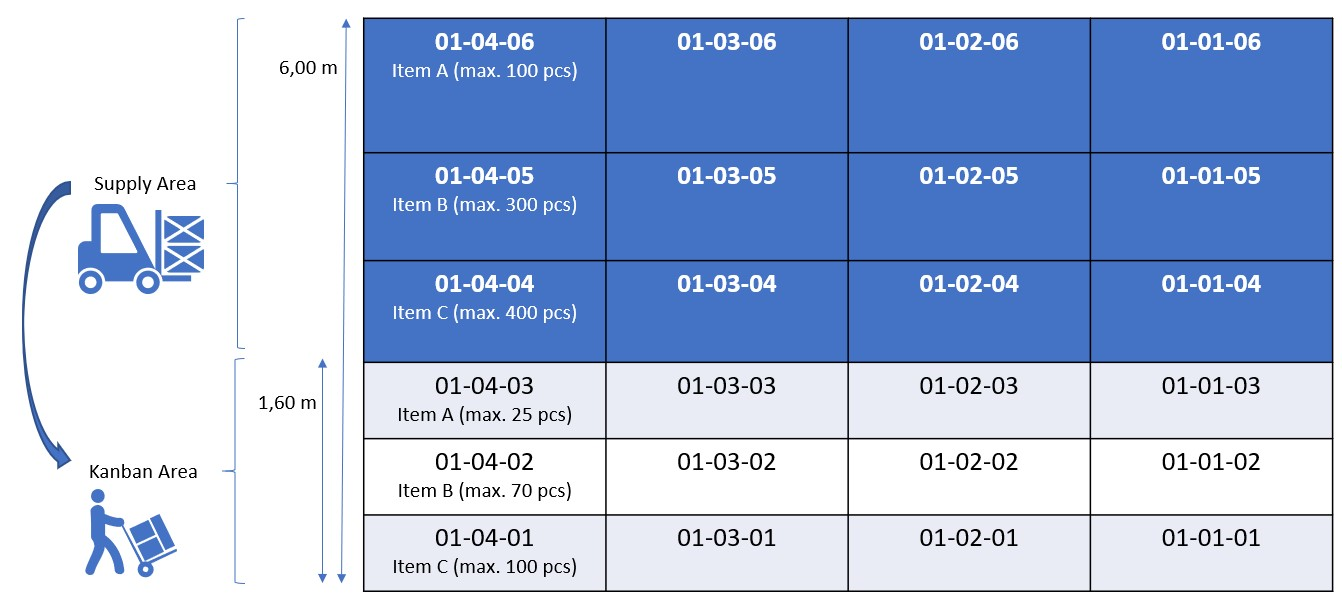

Stock transfer in high-bay warehouses - the goods are transferred to the lower storage bins by forklift, for example, to enable consistent picking by employees without forklifts.

)

)

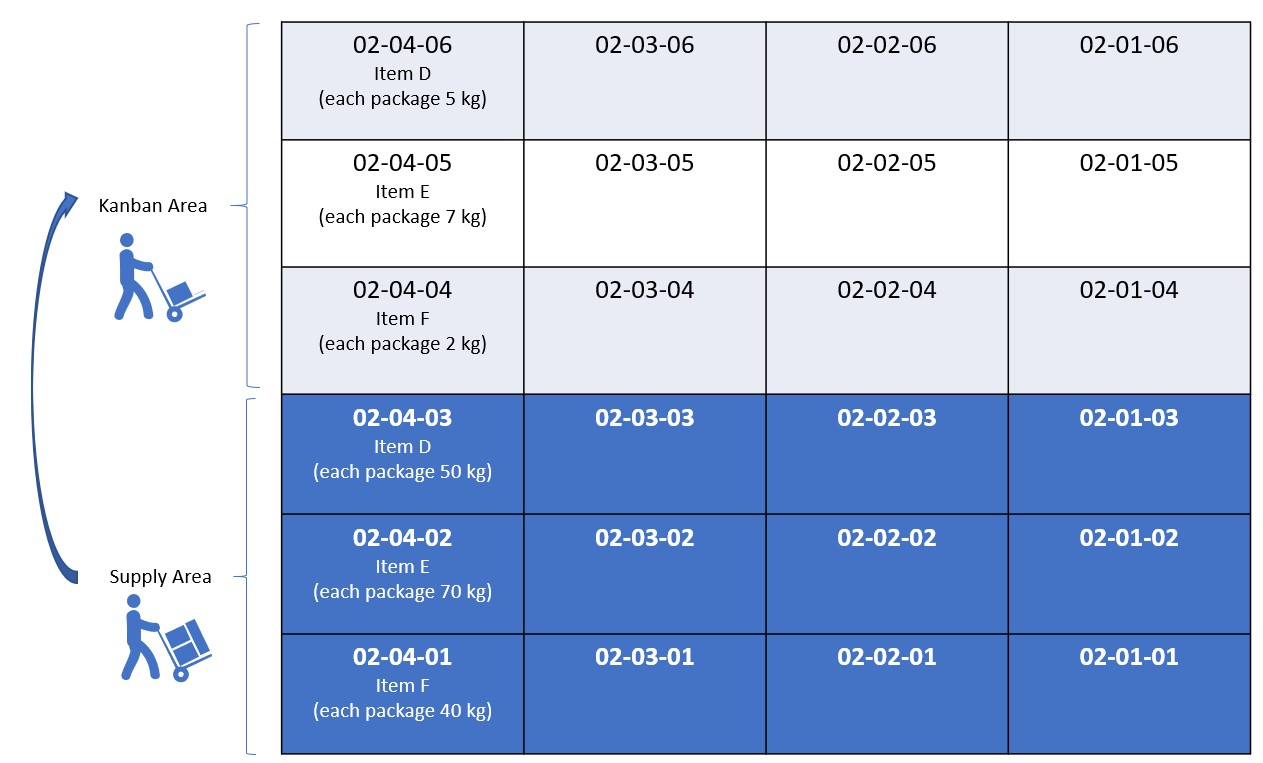

Example 2#

Redistribution of heavy goods present in the picking area (Kanban area) into smaller containers and thus reduced in weight.

)

)

Application in production#

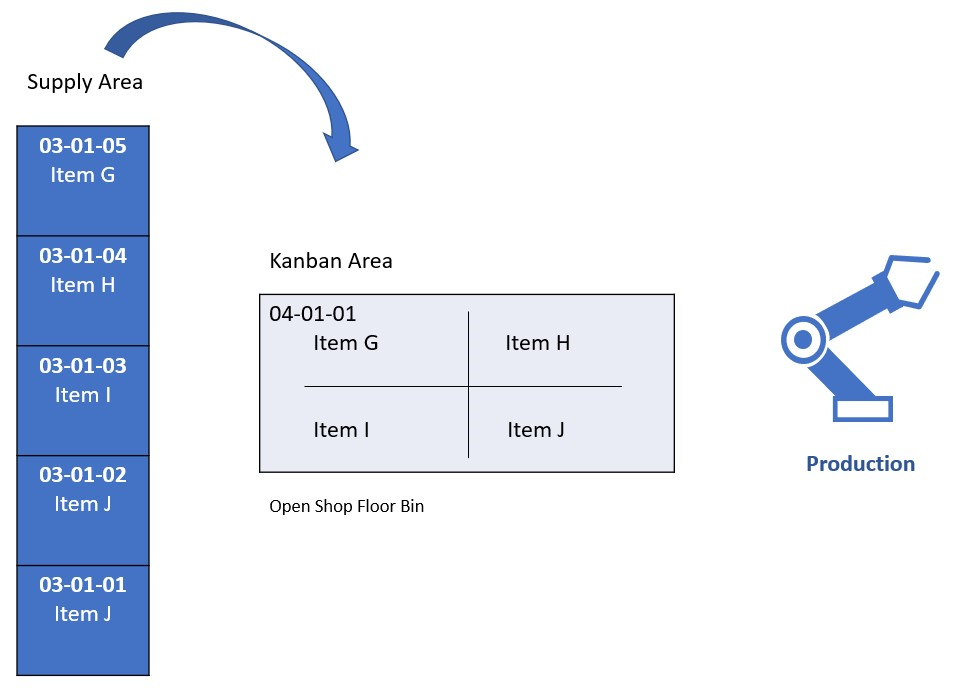

Example 1#

)

)

Storage bin 04-01-01, which is stored in the storage location as an "open production staging bin". The goods in this bin are production components that do not need to be picked explicitly. Since they are continuously needed for production, they are stored in large quantities in storage bin 04-01-01. Consumption staging is automatic (forward or backward).

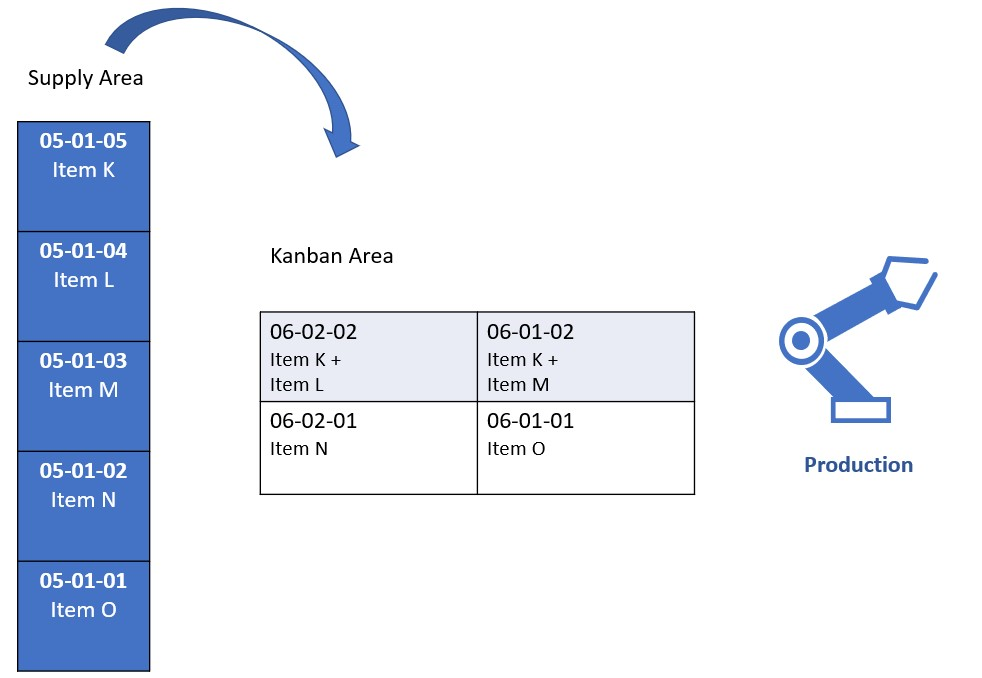

Example 2#

)

)

Storage bins 06-xx-xx contain goods that are prepared for production. This is a manual Staging for consumption picked via logistics documents.

What happens after the free trial#

What happens after the free trial? from KUMAVISION on Vimeo.

-

Microsoft, Microsoft Dynamics, and Microsoft Dynamics 365 are trademarks of the Microsoft group of companies. ↩